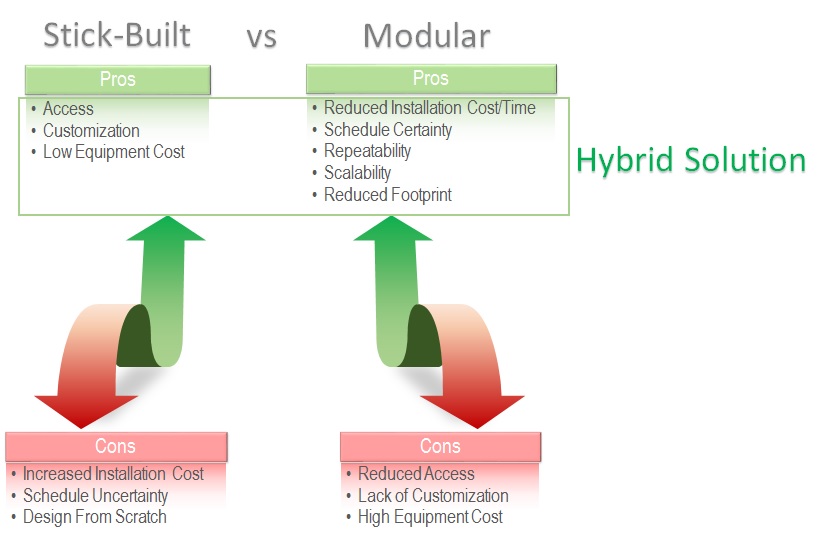

More than 10 years ago, power plants were traditionally stick-built, with each building custom designed and made for that particular plant. The major benefits of this approach were maintenance access and lowest equipment pricing, since a substantial portion of the work was being completed in the field.

Fast forward a few years and three factors started instigating a change in philosophy: centralized organizations, rising construction costs and real estate issues.