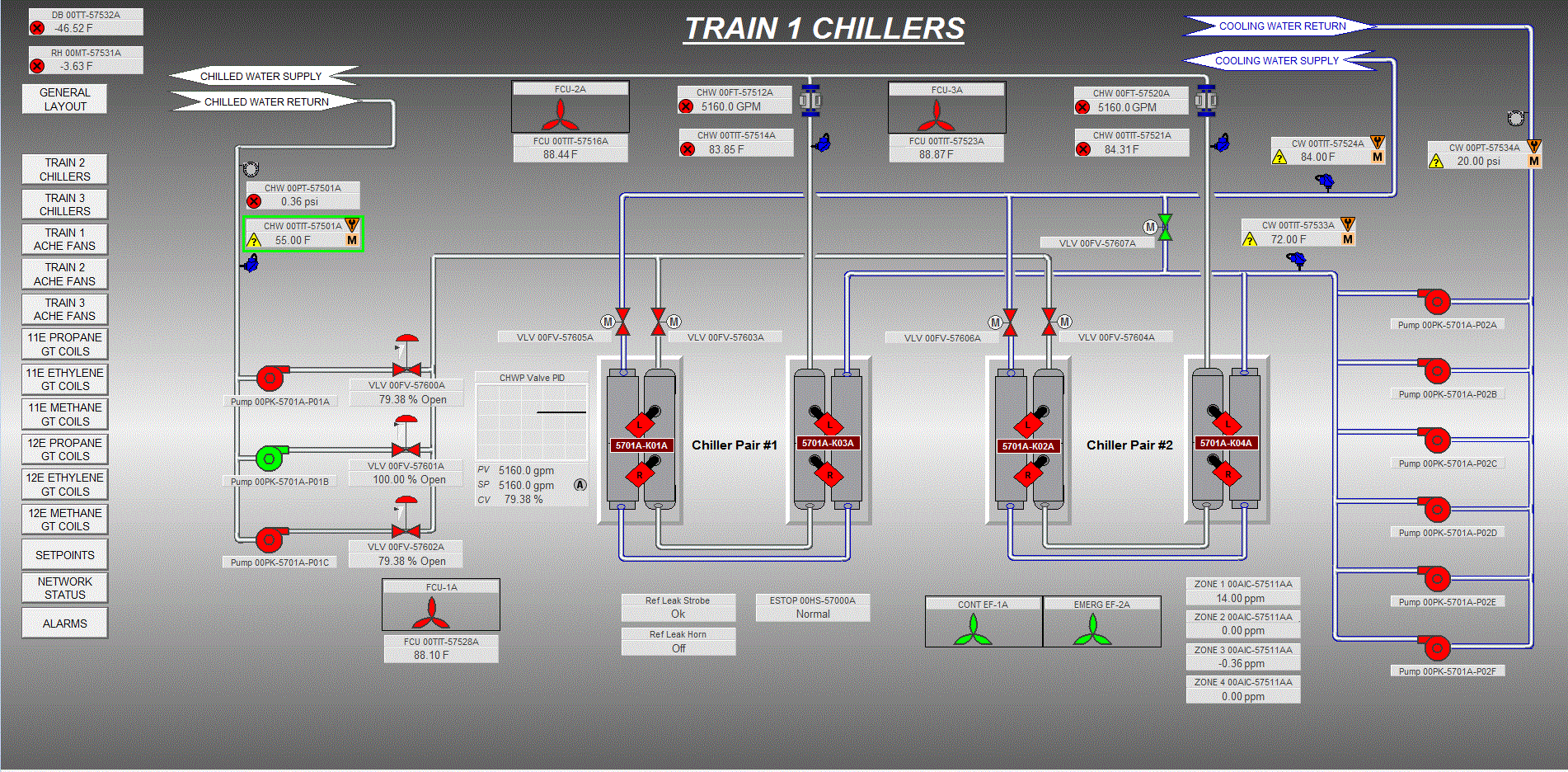

As the true work horses of a TIAC system, chillers are very good at moving the heat from the process water system to the heat rejection system in very large quantities as long as the variables of the process water and heat rejections systems stay within the design limits of the chillers. If these variables venture outside the design limits, the chillers can experience a condition called surge which can cause damage to the chiller’s compressor.

The power market has been subject to rapid changes over the last decade. Renewable generation capacity is contributing a measurable amount of power to the US grid and the growth rate of wind and solar installed capacity has increased by 11% annually from 2015-2018. Despite this growth, dispatchable power cannot be retired but needs to increase as well to support the intermittent nature of renewables. This is especially critical during the warm summer months where power grids are most at risk of not having capacity as a result of higher demand, and experience reduced production from combustion turbines. By making one key change, significant additional dispatchable capacity is available from the existing US combustion turbine fleet without installing more turbines.

The power market has been subject to rapid changes over the last decade. Renewable generation capacity is contributing a measurable amount of power to the US grid and the growth rate of wind and solar installed capacity has increased by 11% annually from 2015-2018. Despite this growth, dispatchable power cannot be retired but needs to increase as well to support the intermittent nature of renewables. This is especially critical during the warm summer months where power grids are most at risk of not having capacity as a result of higher demand, and experience reduced production from combustion turbines. By making one key change, significant additional dispatchable capacity is available from the existing US combustion turbine fleet without installing more turbines.